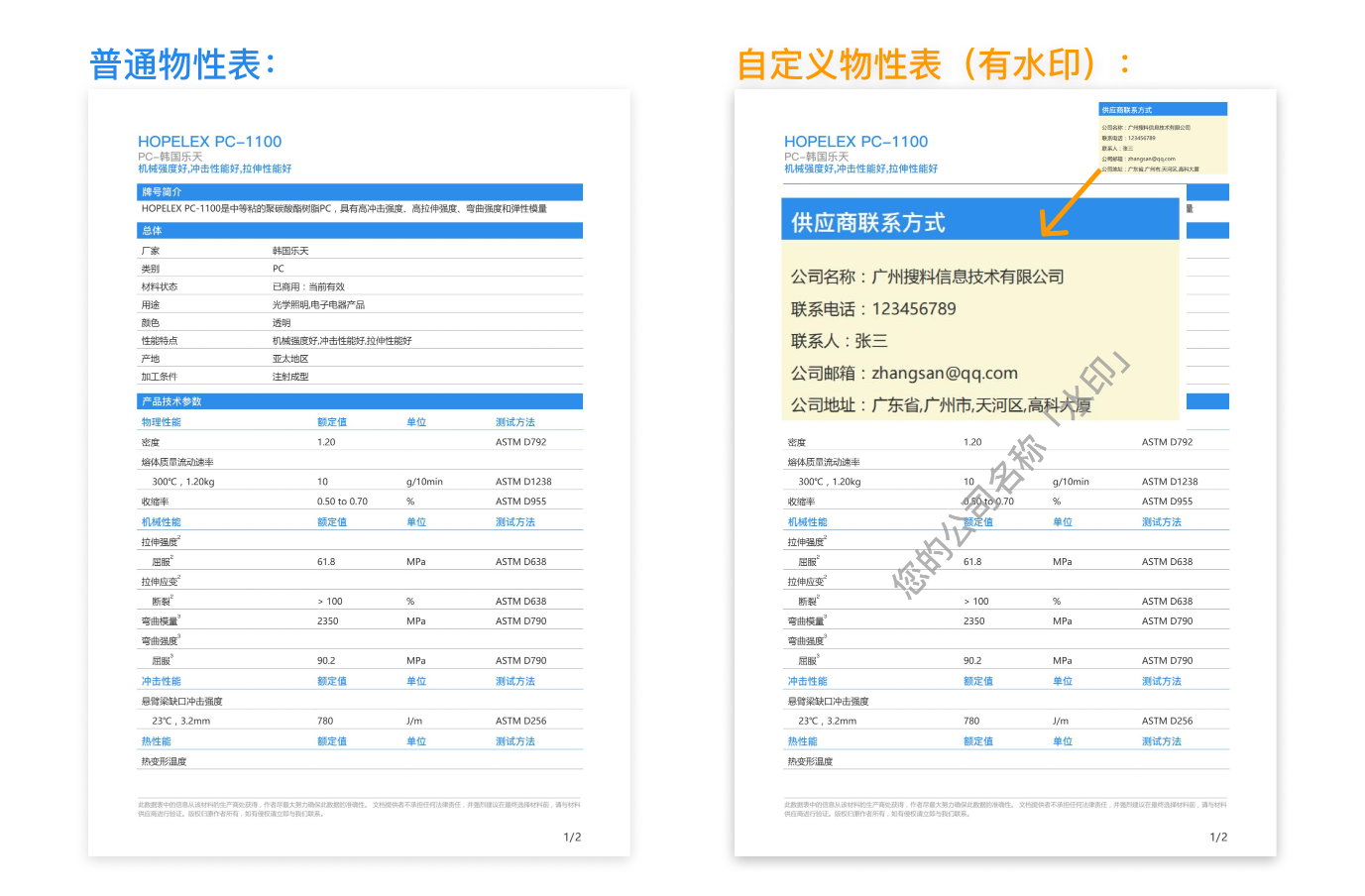

公司信息及水印

| 牌号简介 About |

|---|

| 杜邦Teflon® FEP 9475的典型应用包括小直径、薄壁电线和电缆绝缘、工业薄膜以及通过注射成型制成的复杂或薄壁零件。说明杜邦Teflon® FEP 9475是一种可熔融加工的氟塑料树脂,以颗粒形式提供。它是四氟乙烯和六氟丙烯的共聚物,不含添加剂,符合ASTM D 2116 II型的要求。特氟隆FEP9475具有较高的熔体流动速率和优良的电性能,特别设计用于高速挤压双绞线结构的小尺寸电线上的薄涂层。该树脂具有低压应用所需的电气和机械性能。此外,特氟隆FEP9475比其他大多数氟塑料树脂具有更高的熔体流动速率。这允许更高的挤压速度和更容易的加工,使特氟隆FEP 9475成为生产薄壁挤压件的经济有效的替代品。特氟隆FEP9475的设计和制造是为了提高高频下的耗散系数,并在熔融挤出过程中具有显著的板外阻力。在氮气注入过程中,当与适当的核素一起使用时,它适用于固体绝缘体和泡沫绝缘体。当生产具有氟塑料树脂优良性能的产品需要传统的挤压和成型工艺时,使用特氟隆FEP 9475。与其他热塑性塑料相比,特氟隆FEP9475具有较高的熔融强度和热稳定性,可以提高加工速度。与其他氟塑料相比,耐高温蠕变性能提供了优越的平衡性和最终使用性能。Teflon FEP 9475结合了传统热塑性塑料的易加工性,具有许多类似于聚四氟乙烯的特性。由纯聚四氟乙烯FEP 9475树脂制成的经过适当加工的产品具有氟塑料树脂的优良特性:化学惰性、优异的介电性能、耐热性、韧性和柔韧性、低摩擦系数、不粘特性、可忽略的吸湿性、低可燃性、性能。在极端温度下,具有优异的耐候性。在火焰情况下,特氟隆FEP9475的产品不着火,不促进火焰蔓延。当被其他来源的火焰点燃时,它们的热量贡献很小,并且以很低的烟以缓慢的速度添加。 Typical Application Applications for DuPont™ Teflon® FEP 9475 include small diameter, thin wall wire and cable insulation; industrial film; and intricate or thin wall parts made by injection moulding. Description DuPont™ Teflon® FEP 9475 is a melt-processible fluoroplastic resin available in pellet form. It is a copolymer of tetrafluoroethylene and hexafluoropropylene, without additives, that meets the requirements of ASTM D 2116 type II. With a relatively high melt flow rate and excellent electrical properties, Teflon ® FEP 9475 has been specifically designed for high-speed extrusion of thin coatings on small-gauge wires for twisted-pair constructions. This resin provides the electrical and mechanical properties needed for low voltage applications. In addition, Teflon ® FEP 9475 has a higher melt flow rate than most other fluoroplastic resins. This permits higher extrusion speeds and easier processing, making Teflon ® FEP 9475 a cost-effective alternative for producing thin-wall extrusions. Teflon ® FEP 9475 is designed and made to have improved dissipation factor at high frequencies, and to have significant plate-out resistance in melt extrusion. It is suitable as a solid insulator, and as a foamed insulator when used with an appropriate nucleant in a nitrogen gas injection process. Teflon ® FEP 9475 is used when traditional extrusion and molding processes are required for producing products with the superior properties of a fluoroplastic resin. Compared to other thermoplastics, the high melt strength and thermal stability of Teflon ® FEP 9475 can be used to improve processing rates. Compared with other fluoroplastics, creep resistance at high service temperatures provides a superior balance and level of end-use properties. Teflon ® FEP 9475 combines the processing ease of conventional thermoplastics with many properties similar to those of polytetrafluoroethylene. Properly processed products made from neat Teflon ® FEP 9475 resin provide the superior properties characteristic of fluoroplastic resins: chemical inertness, exceptional dielectric properties, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption, low flammability, performance at temperature extremes, and excellent weather resistance. In a flame situation, products of Teflon ® FEP 9475 resist ignition and do not promote flame spread. When ignited by flame from other sources, their contribution of heat is very small and added at a slow rate with very little smoke. |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

密度 Density |

2.15 | g/cm³ | ASTM D792 |

|

密度 Density |

2.15 | g/cm³ | ISO 1183 |

|

熔体质量流动速率 Melt Flow Rate |

|||

|

372℃,5.0kg 372℃,5.0kg |

30 | g/10min | ASTM D2116 |

|

372℃,5.0kg 372℃,5.0kg |

30 | g/10min | ISO 12086 |

|

吸水率 Water Absorption |

注册或登录后

所有资料免费

|

||

|

24hr 24hr |

注册或登录后

所有资料免费

|

% | ASTM D570 |

|

机械性能 MECHANICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

邵氏硬度 Shore hardness |

注册或登录后

所有资料免费

|

||

|

邵氏 D Shaw's D |

注册或登录后

所有资料免费

|

ASTM D2240 | |

|

邵氏 D Shaw's D |

注册或登录后

所有资料免费

|

ISO 868 | |

|

拉伸强度 tensile strength |

注册或登录后

所有资料免费

|

||

|

屈服,23℃ Yield, 23 ℃ |

注册或登录后

所有资料免费

|

MPa | ASTM D638 |

|

屈服,23℃ Yield, 23 ℃ |

注册或登录后

所有资料免费

|

MPa | ISO 12086 |

|

拉伸应变 Tensile strain |

注册或登录后

所有资料免费

|

||

|

断裂,23℃ Fracture, 23 ℃ |

注册或登录后

所有资料免费

|

% | ASTM D638 |

|

断裂,23℃ Fracture, 23 ℃ |

注册或登录后

所有资料免费

|

% | ISO 12086 |

|

弯曲模量 Flexural Modulus |

注册或登录后

所有资料免费

|

||

|

23℃ 23℃ |

注册或登录后

所有资料免费

|

MPa | ISO 178 |

|

23℃ 23℃ |

注册或登录后

所有资料免费

|

MPa | ASTM D790 |

|

热性能 THERMAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

熔融温度 Melting temperature |

注册或登录后

所有资料免费

|

℃ | ASTM D4591 |

|

电气性能 ELECTRICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

介电强度 Dielectric strength 4 |

注册或登录后

所有资料免费

|

||

|

0.25 mm 0.25 mm 2 , 3 |

注册或登录后

所有资料免费

|

kV/mm | ASTM D149 |

|

0.25 mm 0.25 mm 4 |

注册或登录后

所有资料免费

|

kV/mm | IEC 60243-1 |

|

介电常数 Dielectric constant |

注册或登录后

所有资料免费

|

||

|

1 MHz 1 MHz |

注册或登录后

所有资料免费

|

ASTM D150 | |

|

1.00 GHz 1.00 GHz |

注册或登录后

所有资料免费

|

ASTM D2520 | |

|

相对电容率 Relative permittivity |

注册或登录后

所有资料免费

|

IEC 60250 | |

|

1 MHz 1 MHz |

注册或登录后

所有资料免费

|

IEC 60250 | |

|

1.00 GHz 1.00 GHz |

注册或登录后

所有资料免费

|

IEC 60250 | |

|

耗散因数 Dissipation factor |

注册或登录后

所有资料免费

|

||

|

1 MHz 1 MHz |

注册或登录后

所有资料免费

|

ASTM D150 | |

|

1 GHz 1 GHz |

注册或登录后

所有资料免费

|

ASTM D2520 | |

|

耗散因数 Dissipation factor |

注册或登录后

所有资料免费

|

IEC 60250 | |

|

1 MHz 1 MHz |

注册或登录后

所有资料免费

|

IEC 60250 | |

|

1 GHz 1 GHz |

注册或登录后

所有资料免费

|

IEC 60250 | |

|

阻燃性能 FLAME CHARACTERISTICS |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

阻燃等级 Flame Class Rating |

注册或登录后

所有资料免费

|

UL 94 | |

|

极限氧指数 Oxygen Index |

注册或登录后

所有资料免费

|

% | ASTM D2863 |

|

极限氧指数 Oxygen Index |

注册或登录后

所有资料免费

|

% | ISO 4589-2 |

|

补充信息 Supplementary information |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

Critical Shear Rate(372℃) Critical Shear Rate(372℃) |

注册或登录后

所有资料免费

|

sec^-1 | Internal Method |

|

MIT耐折强度(8 mil film,200.0 µm) MIT flexural strength (8 mil film, 200.0 µ m) |

注册或登录后

所有资料免费

|

Cycles | ASTM D2176 |

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

| 2 方法A(短时间) |

| 3 .25 mm film |

| 4 Short Time, .25 mm film |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付