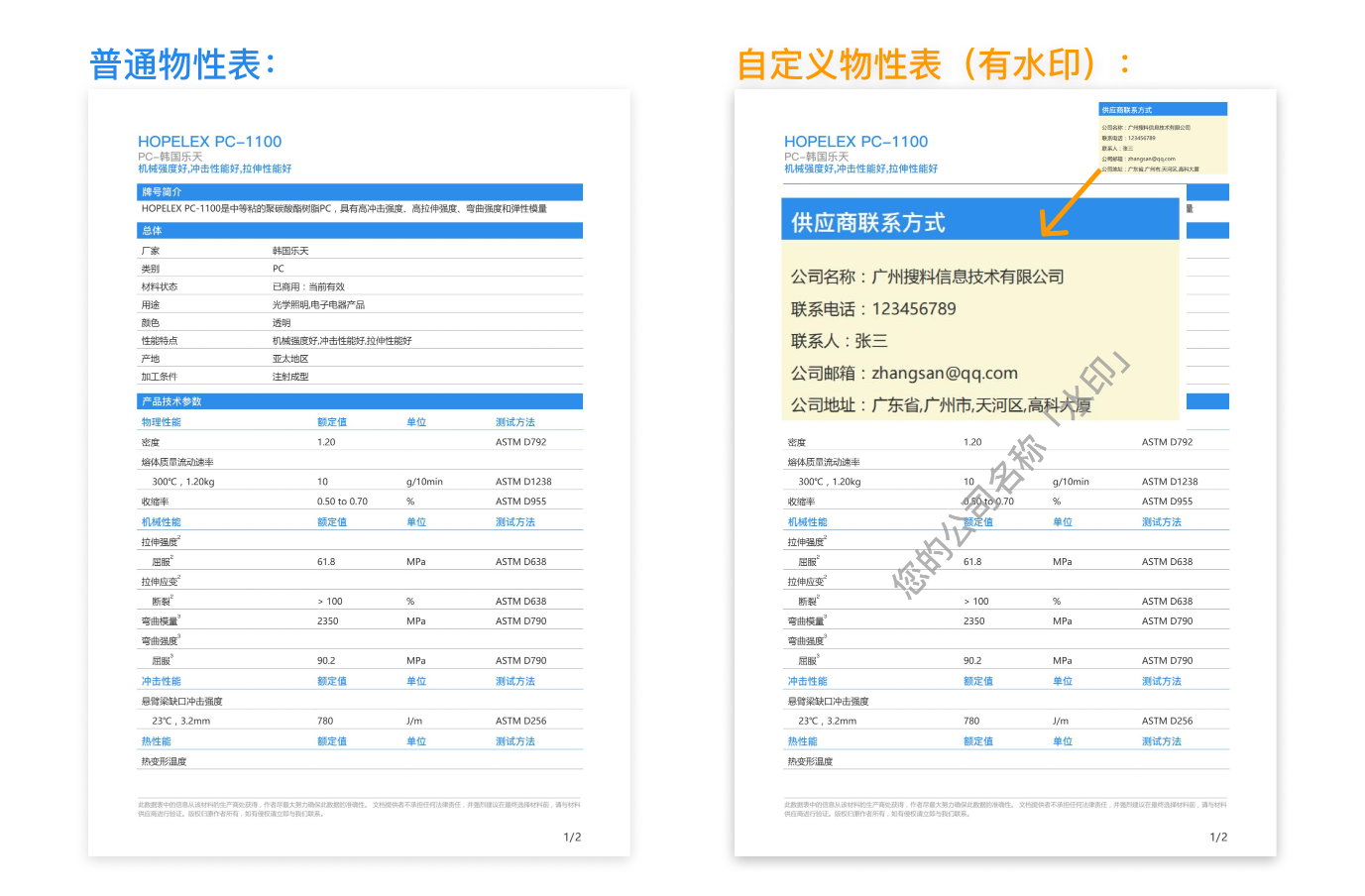

公司信息及水印

| 牌号简介 About |

|---|

| BorPEX™ HE2590是专为生产交联管(PE-X)而设计的高分子量高密度聚乙烯。该产品适用于单管和多层管,然后将集成Evoh层的塑料多层管与铝多层管区分开来。BorPEX™ HE2590旨在满足以下标准和法规,如果适用适当的工业制造标准程序,并实施持续质量体系。DIN 16892 DIN 16893 EN ISO 15875 ASTM F 876 BorPEX HE2590 is a high molecular weight, high density polyethylene specially designed for production of crosslinked pipes (PE-X) Applications BorPEX HE2590 is recommended for the production of crosslinked pipes used in Domestic water Heating Relining Plumbing Industrial applications Domestic gas District heating The product is used for single as well as for multilayer pipes, where you then differentiate between plastic multilayer with integrated EVOH layer and aluminium multilayer pipes. Specifications BorPEX HE2590 is intended to fulfill following standards and regulations, in case of appropriate industrial manufacturing standard procedures applied and a continuous quality system is implemented. DIN 16892 DIN 16893 EN ISO 15875 ASTM F 876 Special features BorPEX HE2590 is a ready made compound in pellet form for the production of crosslinkable pipes by the electron beam beta-irradiation process (PE-Xc) and included is a specially selected additive package to ensure: Enhanced processability Economical pipe production Excellent product consistency Effective crosslinking behaviour High temperature resistance High resistance to additive washout |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

密度 Density 3 |

0.944 | g/cm³ | ISO 1183 |

|

熔体质量流动速率 Melt Flow Rate |

|||

|

190℃,21.6kg 190℃,21.6kg |

8.5 | g/10min | ISO 1133 |

|

机械性能 MECHANICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

拉伸强度 tensile strength |

|||

|

屈服 yield |

18.0 | MPa | ISO 527-2/50 |

|

拉伸应变 Tensile strain |

|||

|

断裂 fracture |

> 600 | % | ISO 527-2 |

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

| 2 Compound |

|

【新闻资讯】查看全部

阿科玛Pebax聚酰胺赋能迪卡侬高性能跑鞋品牌KIPRUN

2022-09-22 扫描上图二维码,可以免费下载 搜料 APP 9月初,阿科玛集团与运动装备设计品牌迪卡侬(DECATHLON)发布合作成果:跑鞋品牌KIPRUN旗下的新型KD900X高性能跑鞋。 KIPRUN选择阿科玛及其Peba |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付