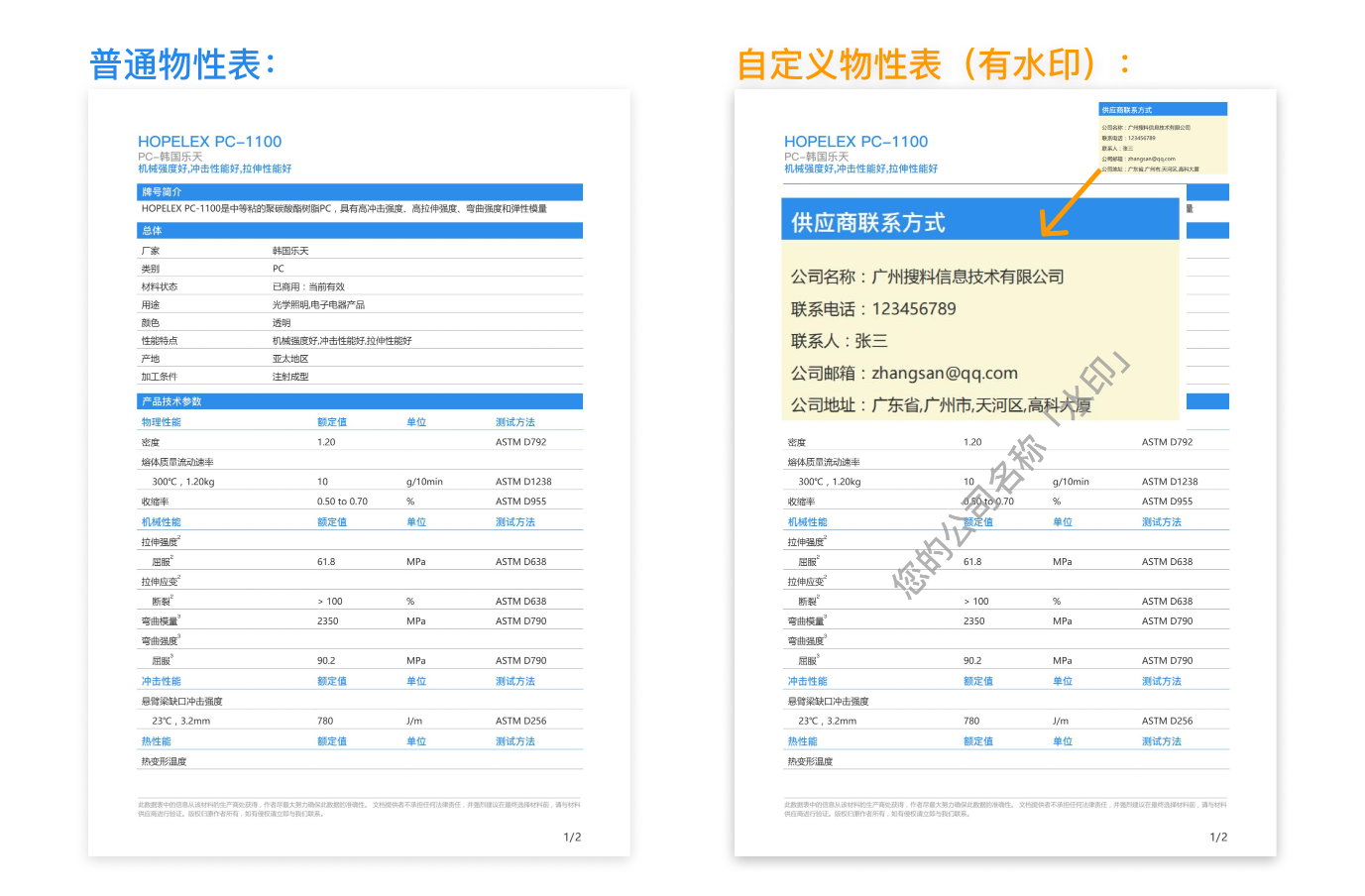

公司信息及水印

| 牌号简介 About |

|---|

| MEGOLON™ S530是一种热塑性、无卤、阻燃的护套化合物,具有很好的柔韧性和较低的杨氏模量。它是专门为电信电缆应用开发的,具有高氧指数和增强的防火性能。 MEGOLON™ S530 is a thermoplastic, halogen free, fire retardant sheathing compound possessing very good flexibility and a low Young's Modulus. It has been specifically developed for telecommunication cable applications and exhibits a high oxygen index and enhanced fire test performance. |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

密度 Density |

1.58 | g/cm³ | ASTM D792 |

|

熔体质量流动速率 Melt Flow Rate |

|||

|

150℃,21.6kg 150℃,21.6kg |

1.5 | g/10min | ISO 1133 |

|

门尼粘度 Mooney viscosity |

|||

|

ML 1+4,140℃ ML 1+4,140℃ |

50 | MU | ASTM D1646 |

|

机械性能 MECHANICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

邵氏硬度 Shore hardness |

|||

|

邵氏 D Shaw's D |

45 | ASTM D2240 | |

|

拉伸强度 tensile strength |

|||

|

-- -- 2 |

14.5 | MPa | IEC 60811-1-2 |

|

-- -- |

MPa | IEC 60811-1-1 | |

|

拉伸应变 Tensile strain |

|||

|

断裂 fracture 2 |

% | IEC 60811-1-2 | |

|

断裂 fracture |

% | IEC 60811-1-1 | |

|

拉伸应变 Tensile strain |

|||

|

断裂,4 hr,在IRM 902油中,70℃ Fracture, 4 hours, in IRM 902 oil, 70 ℃ |

% | ||

|

断裂,4 hr,在SAE 20油中,70℃ Fracture, 4 hr, in SAE 20 oil, 70 ℃ |

% | ||

|

断裂,7 days,在IRM 902油中,23℃ Fracture, 7 days, in IRM 902 oil, 23 ℃ |

% | ||

|

断裂,7 days,在IRM 903油中,23℃ Fracture, 7 days, in IRM 903 oil, 23 ℃ |

% | ||

|

拉伸强度 tensile strength |

|||

|

after 4 hours,in IRM 902 Oil:70℃ after 4 hours,in IRM 902 Oil:70℃ |

MPa | ||

|

after 4 hours,in SAE 20 Oil:70℃ after 4 hours,in SAE 20 Oil:70℃ |

MPa | ||

|

after 7 days,in IRM 902 Oil:23℃ after 7 days,in IRM 902 Oil:23℃ |

MPa | ||

|

after 7 days,in IRM 903 Oil:23℃ after 7 days,in IRM 903 Oil:23℃ |

MPa | ||

|

弹性体 elastic body |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

撕裂强度 tear strength |

kN/m | BS 6469 99.1 | |

|

热性能 THERMAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

低温伸长率 Low temperature elongation |

|||

|

-25℃ -25℃ |

% | IEC 60811-1-4 | |

|

低温冲击 Low temperature shock |

|||

|

-25℃ -25℃ |

IEC 60811-1-4 | ||

|

Hot Deformation(90℃) Hot Deformation(90℃) |

% | BS 6469 99.1 | |

|

热压试验 Hot press test |

|||

|

80℃ 80℃ |

% | IEC 60811-3-1 | |

|

老化性能 Aging performance |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

拉伸强度的变化率 在空气中(100℃,168 hr) The rate of change in tensile strength in air (100 ℃, 168 hr) |

% | ||

|

Change in Tensile Strain at Break in Air(100℃,168 hr) Change in Tensile Strain at Break in Air(100℃,168 hr) |

% | ||

|

拉伸强度的变化率 The rate of change in tensile strength |

|||

|

23℃,168 hr,in IRM 902 Oil 23℃,168 hr,in IRM 902 Oil |

% | ||

|

23℃,168 hr,in IRM 903 Oil 23℃,168 hr,in IRM 903 Oil |

% | ||

|

70℃,4 hr,in IRM 902 Oil 70℃,4 hr,in IRM 902 Oil |

% | ||

|

70℃,4 hr,in SAE 20 Oil 70℃,4 hr,in SAE 20 Oil |

% | ||

|

断裂时拉伸应力变化 Changes in tensile stress during fracture |

|||

|

23℃,168 hr,in IRM 902 Oil 23℃,168 hr,in IRM 902 Oil |

% | ||

|

23℃,168 hr,in IRM 903 Oil 23℃,168 hr,in IRM 903 Oil |

% | ||

|

70℃,4 hr,in IRM 902 Oil 70℃,4 hr,in IRM 902 Oil |

% | ||

|

70℃,4 hr,in SAE 20 Oil 70℃,4 hr,in SAE 20 Oil |

% | ||

|

体积变化 Volume change |

|||

|

23℃,168 hr,in IRM 902 Oil 23℃,168 hr,in IRM 902 Oil |

% | ||

|

23℃,168 hr,in IRM 903 Oil 23℃,168 hr,in IRM 903 Oil |

% | ||

|

70℃,4 hr,in IRM 902 Oil 70℃,4 hr,in IRM 902 Oil |

% | ||

|

电气性能 Electrical performance |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

介电常数 Dielectric constant |

|||

|

50 Hz 50 Hz |

ASTM D150 | ||

|

耗散因数 Dissipation factor |

|||

|

50 Hz 50 Hz |

ASTM D150 | ||

|

绝缘电阻 insulation resistance |

BS 6469 99.2 | ||

|

20℃ 20℃ |

ohms·cm | BS 6469 99.2 | |

|

after 12 hours immersion in water:20℃ after 12 hours immersion in water:20℃ |

ohms·cm | BS 6469 99.2 | |

|

阻燃性能 FLAME CHARACTERISTICS |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

极限氧指数 Extreme oxygen index |

% | ISO 4589-2 | |

|

酸性气体排放传导性 Conductivity of acidic gas emissions |

µS/cm | IEC 60754-2 | |

|

酸性气体排放 pH Acid gas emission pH |

IEC 60754-2 | ||

|

可燃性温度指数 Flammability temperature index |

℃ | ISO 4589-3 | |

|

烟雾密度 Smoke density |

ASTM E662 | ||

|

Flaming mode Flaming mode 3 |

Ds | ASTM E662 | |

|

非燃烧模式 Non combustion mode 4 |

Ds | ASTM E662 | |

|

毒性 toxicity |

NES 713 | ||

|

补充信息 Supplementary information |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

Halogen Acid Gas Evolution Halogen Acid Gas Evolution |

% | IEC 60754-1 | |

|

耐臭氧性 Ozone resistance |

ASTM D470 | ||

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

| 2 after 7 days at 100°C |

| 3 Time to maximum: 11 minutes |

| 4 Time to maximum: 12 minutes |

|

【新闻资讯】查看全部

高附加值专用聚烯烃树脂生产技术自主化再添关键性成果!

2021-09-17 搜料网资讯: 采用石化院自主研发的淤浆工艺串联聚合用聚乙烯催化剂PSE-CX2,继在兰州石化17万吨/年三井淤浆聚乙烯装置首次工业试验成功后,生产的耐热聚乙烯管材专用树脂日前在中 |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付